Single point incremental forming spif is a sheet metal forming technique that is gradually evolving towards industrial applicability.

Fundamental studies on the incremental sheet metal forming technique.

Incremental sheet forming is a flexible and versatile process with a promising future in the batch production and prototyping sectors.

The idea of incremental forming technique has been investigated for production of sheet metal components.

With decreased design time and negligible production time incremental sheet forming provides reliability flexibility and quality while being an economical option in contrast to the traditional forming process.

With this technique the forming limit curve flc appears in a different pattern revealing an enhanced formability compared to conventional forming techniques.

Several aspects of incremental forming an innovative sheet metal forming process were studied.

As recent market analysis studies have shown accuracy is one of the most important limiting factors for the deployment of spif in industrial applications.

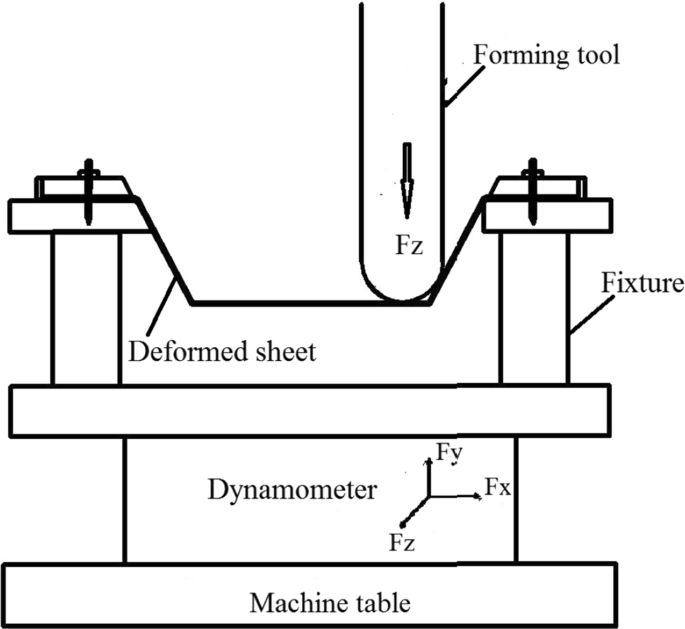

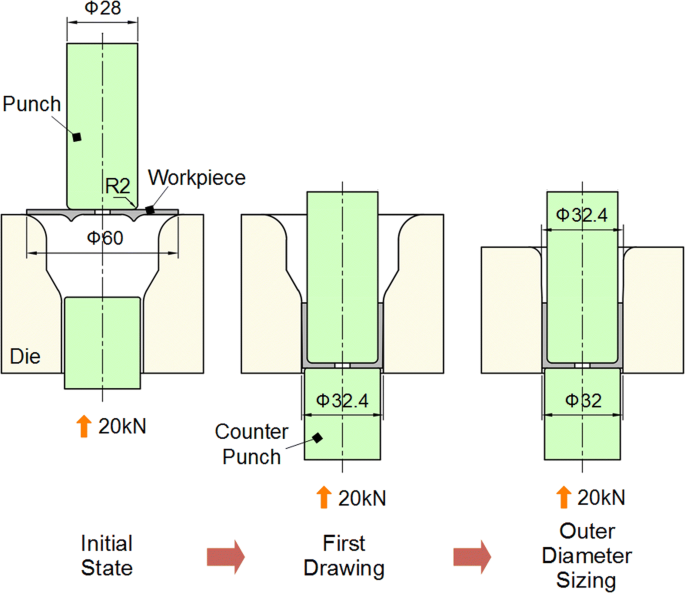

Incremental sheet forming or isf also known as single point forming is a sheet metal forming technique where a sheet is formed into the final workpiece by a series of small incremental deformations.

Download citation fundamental studies on the incremental sheet metal forming technique the idea of incremental forming technique has been investigated for production of sheet metal components.

Generally the sheet is formed by a round tipped tool typically 5 to 20mm in diameter.

Secondly the effect of the tool diameter on the surface texture of a part was investigated.

Firstly an optimal combination of tool and lubricant was explored to form the ta1 commercial titanium sheet metal parts.

Also conventional techniques such as stretching and deep drawing processes were simulated by a commercial fem package for the purpose of comparison in the aspect of forming capabilities.

Also conventional techniques such as stretching and deep drawing processes were simulated by a commercial fem package for the purpose of comparison in the aspect of form ing capabilities.

Fundamental studies on the incremental sheet metal forming technique.

However studies have shown that it can be applied to polymer and composite sheets too.